Coated Film Products

Barrier Film

-Others-

We offer a range of barrier film coated with PVdC or PVA.

PVdC (Polyvinylidene Chloride) Coated BOPP Film

Cenessy KOP is PVdC coated BOPP film.

You can gain excellent oxygen, moisture and aroma barrier from the PVdC coating layer.

The PVdC layer is stable against humidity, you can enjoy these functions under various humidity conditions.

The PVdC coating layer keeps its barrier functions even if you give physical distortion onto KOP.

We offer you widely range of KOP with various functuons; thermal resistance, anti-statics and UV cutting.

| Cenessy KOP | Type Name | Thickness | Oxygen Barrier |

Moisture Barrier |

Corona Treatment (Uncoated Side) |

Antistatic | Thermal Processing |

Additonal Functions |

Applications | Remarks |

|---|---|---|---|---|---|---|---|---|---|---|

| EG10 | 20 | 120 | 6.0 | – | – | – | for General foods | |||

| 30 | 120 | 4.0 | – | – | – | |||||

| EG15 | 20 | 120 | 6.0 | ○ | – | – | for General foods | |||

| 1000 | 20 | 80 | 5.0 | – | – | – | for General foods | |||

| 30 | 80 | 3.5 | – | – | – | |||||

| 1050 | 20 | 80 | 5.0 | ○ | – | – | for General foods | |||

| 30 | 80 | 3.5 | ○ | – | – | Inquire please, regarding supply system. |

||||

| 6000 | 20 | 80 | 5.0 | – | – | ○ | for General foods, Thermal processing (<100℃) |

|||

| 30 | 80 | 3.5 | – | – | ○ | |||||

| 6050 | 20 | 80 | 5.0 | ○ | – | ○ | for General foods, Thermal processing (<100℃) |

|||

| 30 | 80 | 3.5 | ○ | – | ○ | Inquire please, regarding supply system. |

||||

| HB60 | 20 | 25 | 2.5 | – | – | ○ | for General foods, Thermal processing (<100℃) |

|||

| 25 | 25 | 2.3 | – | – | ○ | Inquire please, regarding supply system. |

||||

| 30 | 25 | 2.0 | – | – | ○ | Inquire please, regarding supply system. |

||||

| HB65 | 20 | 25 | 2.5 | ○ | – | ○ | for General foods, Thermal processing (<100℃) |

|||

| WVZ | 20 | 15 | 1.0 | – | – | – | Ultra high barrier |

Inquire please, regarding supply system. |

||

| FB03 | 20 | 80 | 5.0 | – | ○ | – | for Powdered contents/Dried foods, for Vertical packaging system |

|||

| 30 | 80 | 3.5 | – | ○ | – | |||||

| FB02 | 20 | 25 | 2.5 | – | ○ | – | for Powdered contents/Dried foods, for Vertical packaging system |

Inquire please, regarding supply system. |

||

| 30 | 25 | 2.0 | – | ○ | – | Inquire please, regarding supply system. |

||||

| KG02 | 20 | 35 | 2.5 | – | – | – | Exclusively for handwarmer packaging |

Inquire please, regarding supply system. |

||

| 30 | 35 | 2.0 | – | – | – | |||||

| PGX | 20 | 20 | 2.0 | – | – | ○ | for Pickles | |||

| UV30 | 20 | 35 | 3.0 | – | – | ○ | 80% block to UV lay |

Prevent coloring with UV cutting |

* Unit: Oxygen barrier = ml/mi/24Hrs/MPa at 20°C ×80%RH

* Unit: Moisture barrier = g/m/24Hrs at 40°C ×90%RH

* The properties are representative values and not guaranteed values.

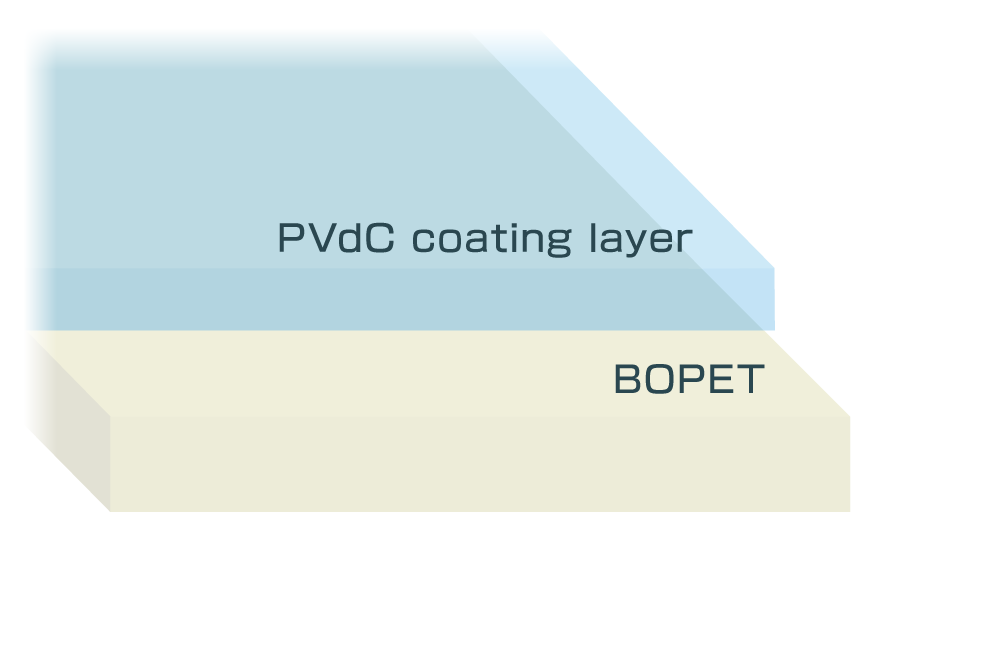

PVdC (Polyvinylidene Chloride) Coated BOPET Film

Cenessy KET is PVdC coated BOPET film.

You can gain excellent oxygen, moisture and aroma barrier from the PVdC coating layer.

The PVdC layer is stable against humidity, you can enjoy these functions under various humidity conditions.

The PVdC coating layer keeps its barrier functions even if you give physical distortion onto KET.

We offer you widely range of KOP with various functuons; thermal resistance and anti-statics.

| Cenessy KET | Type Name | Thickness | Oxygen Barrier |

Moisture barrier |

Corona Treatment (Uncoated Side) |

Antistatic | Thermal Processing |

Additonal Functions |

Applications | Remarks |

|---|---|---|---|---|---|---|---|---|---|---|

| 1000 | 12 | 80 | 10.0 | – | – | – | for General foods | |||

| 6000 | 12 | 80 | 10.0 | – | – | ○ | for General foods, Thermal processing (<100℃) |

|||

| 6050 | 12 | 80 | 10.0 | ○ | – | ○ | for General foods, Thermal processing (<100℃) |

Inquire please, regarding supply system. |

||

| HB60 | 12 | 25 | 3.5 | – | – | ○ | for General foods, Thermal processing (<100℃) |

|||

| FB03 | 12 | 80 | 10.0 | – | ○ | – | for Powdered contents/Dried foods, for Vertical packaging system |

|||

| FB02 | 12 | 25 | 3.5 | – | ○ | – | for Powdered contents/Dried foods, for Vertical packaging system |

|||

| MTH | 12 | 35 | 4.5 | – | – | – | Matte (opaque) |

for General foods | Inquire please, regarding supply system. |

* Unit: Oxygen barrier = ml/mi/24Hrs/MPa at 20°C ×80%RH

* Unit: Moisture barrier = g/m/24Hrs at 40°C ×90%RH

* The properties are representative values and not guaranteed values.

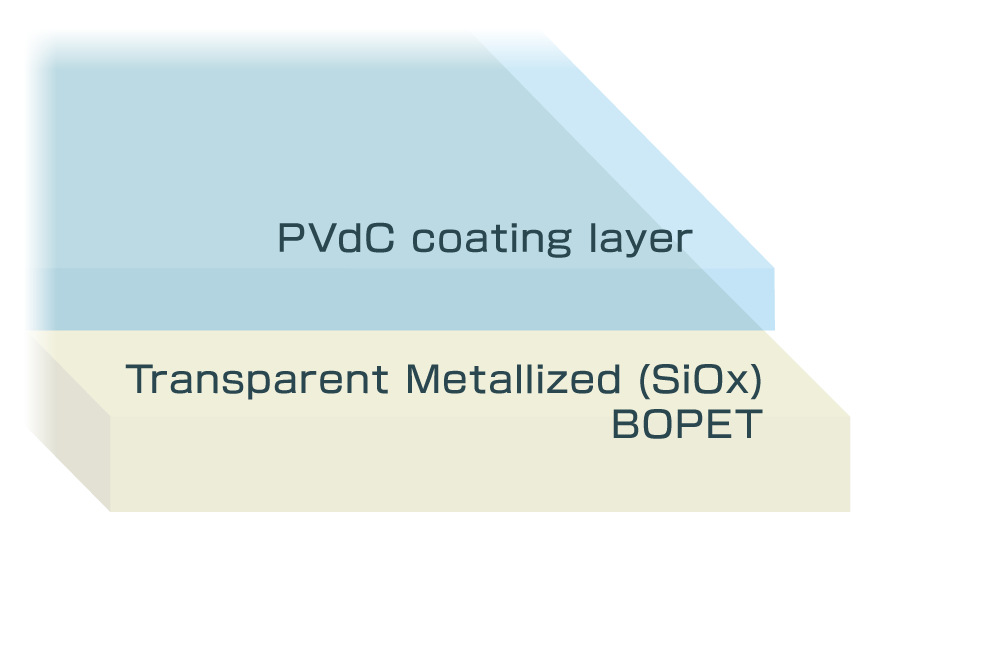

Combination of Transparet (SiOx) Metallization

and PVdC Coating to BOPET Film

Cenessy SWB is PVdC coated BOPET film above SiOx layer.

The structure is PVdC coating layer, SiOx metallized layer and then based-BOPET film.

Thanks to the combination of PVdC coating and SiOx layer, you can enjoy ultra high barrier with transparency.

You can gain ultra high barrier both OTR and WVTR, while simultaneously gaining the resistance to physical distortion.

| Cenessy SWB | Type Name | Thickness | Oxygen Barrier |

Moisture barrier |

Corona Treatment (Uncoated Side) |

Antistatic | Thermal Processing |

Applications | Remarks |

|---|---|---|---|---|---|---|---|---|---|

| SBX | 12 | 2 | 0.05 | – | – | – | High stability moisture barrier under various humidity condition. Replaceable from Alu foil. |

Inquire please, regarding supply system. |

* Unit: Oxygen barrier = ml/mi/24Hrs/MPa at 20°C ×80%RH

* Unit: Moisture barrier = g/m/24Hrs at 40°C ×90%RH

* The properties are representative values and not guaranteed values.

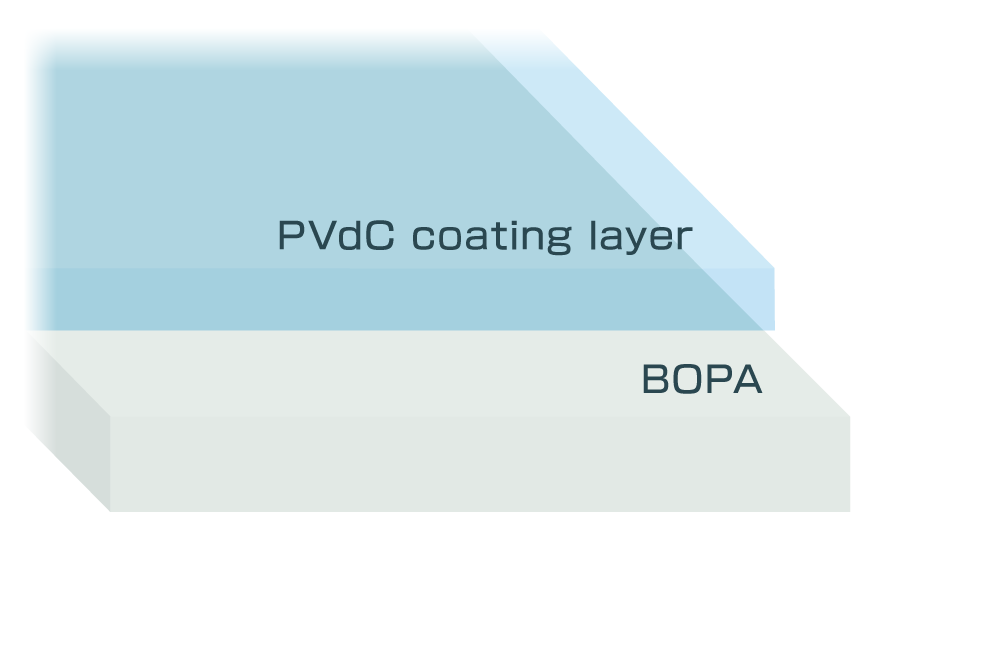

PVdC (Polyvinylidene Chloride) Coated BOPA Film

Cenessy KON is PVdC coated BOPA film.

You can gain excellent oxygen, moisture and aroma barrier from the PVdC coating layer.

The PVdC layer is stable against humidity, you can enjoy these functions under various humidity conditions.

The PVdC coating layer keeps its barrier functions even if you give physical distortion onto KON.

We offer you widely range of KON with various functuons; thermal resistance and anti-statics.

| Cenessy KON | Type Name | Thickness | Oxygen Barrier | Moisture barrier |

Corona Treatment (Uncoated Side) |

Antistatic | Thermal Processing |

Additonal Functions |

Applications | Remarks |

|---|---|---|---|---|---|---|---|---|---|---|

| 1100 | 15 | 80 | 10.0 | – | – | – | for General foods | |||

| 6100 | 15 | 80 | 10.0 | – | – | ○ | for General foods, Thermal processing (<100℃) |

|||

| HB60 | 15 | 30 | 5.0 | – | – | ○ | for General foods, Thermal processing (<100℃) |

|||

| RTS | 15 | 80 | 10.0 | – | – | ○ | Thermal processing (≦120℃×30min) |

for General foods, Thermal processing (≦120℃×30min) |

||

| RTH | 15 | 30 | 5.0 | – | – | ○ | Thermal processing (≦120℃×30min) |

for General foods, Thermal processing (≦120℃×30min) |

* Unit: Oxygen barrier = ml/mi/24Hrs/MPa at 20°C ×80%RH

* Unit: Moisture barrier = g/m/24Hrs at 40°C ×90%RH

* The properties are representative values and not guaranteed values.

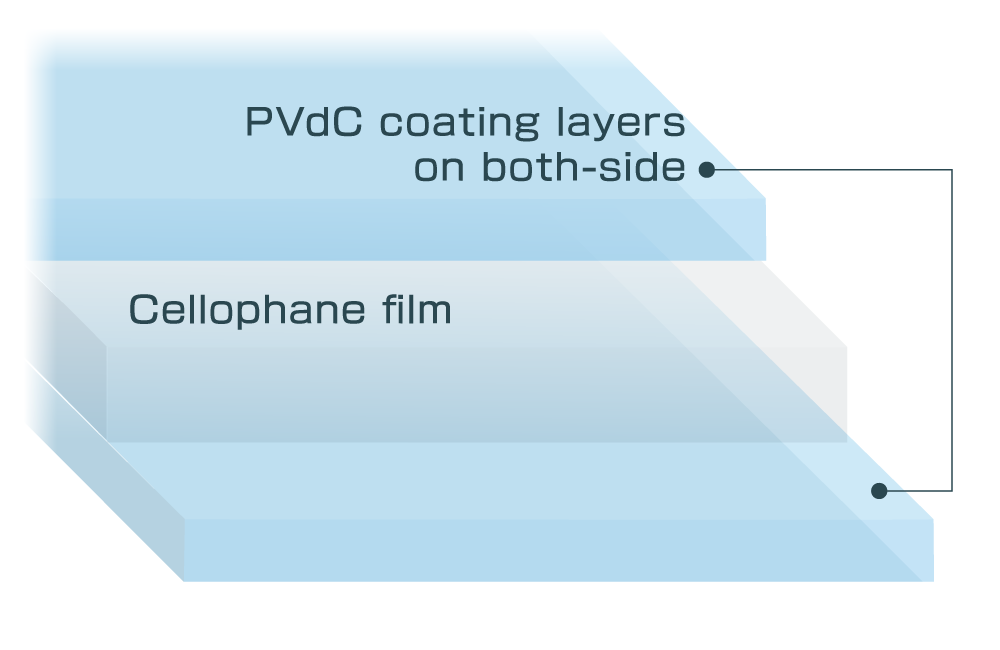

PVdC (Polyvinylidene Chloride) Coated Cellophane Film

K,KM-Cerusi are both-side PVdC coated cellophane film.

The nature of cellophane is kept on K, KM-Cerusi even after PVdC coating, ex. easy tearing etc.

In addition, you can enjoy good oxygen, moisture and aroma barrier.

The PVdC coating layer keeps its barrier functions even if you give physical distortion onto K,KM-Cerusi.

|

K,KM-Cerusi are applicable to ‘Biomass mark’ operated by Japan Organics Recycling Association. K,KM-Cerusi are certified to contain 75% biomass source by the Association. |

|---|

| Type Name | Thickness | Moisture barrier |

Corona Treatment (Uncoated Side) |

Antistatic | Thermal Processing |

Applications | Remarks | |

|---|---|---|---|---|---|---|---|---|

| KM-Cerusi | G | 300 | 30.0 | – | – | – | for General lamination | Inquire please, regarding supply system. |

| K-Cerusi | G | 350 | 30.0 | – | – | – | for General lamination | Inquire please, regarding supply system. |

* Unit: Moisture barrier = g/m/24Hrs at 40°C ×90%RH

* The properties are representative values and not guaranteed values.

PVA (Polyvinyl Alcohol) Coated BOPP Film

Cenessy XOP is PVA coated BOPP film.

You can gain excellent oxygen, moisture and aroma barrier from the PVA coating layer.

These functions are stable against physical distortion.

XOP is only applicable to package of lower activity value contents (under 0.5).

| Cenessy XOP | Type Name | Thickness | Oxygen Barrier | Moisture barrier |

Corona Treatment (Uncoated Side) |

Antistatic | Thermal Processing |

Applications | Remarks |

|---|---|---|---|---|---|---|---|---|---|

| 5000 | 20 | 10 | 4.0 | – | – | – | for Food packaging with water activity below 0.5 |

||

| 30 | 10 | 3.0 | – | – | – | for Food packaging with water activity below 0.5 |

|||

| 5050 | 20 | 10 | 4.0 | ○ | – | – | for Food packaging with water activity below 0.5 |

||

| 5000FB | 20 | 10 | 4.0 | – | ○ | – | for Food packaging with water activity below 0.5 |

Inquire please, regarding supply system. |

|

| 30 | 10 | 3.0 | – | ○ | – | for Food packaging with water activity below 0.5 |

Inquire please, regarding supply system. |

* Unit: Oxygen barrier = ml/mi/24Hrs/MPa at 20°C ×80%RH

* Unit: Moisture barrier = g/m/24Hrs at 40°C ×90%RH

* The properties are representative values and not guaranteed values.

Special PVA (Spoecial Polyvinyl Alcohol) Coated BOPP Film

Cenessy XOP-S is special PVA coated BOPA film.

XOP-S has better stability against humidity than XOP.

You can apply XOP-S to package to higher water activity valiue contents than XOP.

You can gain excellet oxygen, moisture and aroma barrier from the special PVA coating layer.

These functions are stable against physical distortion.

XOP-S is applicable to package of lower activity value contents (under 0.7).

| Cenessy XOP-S | Type Name | Thickness | Oxygen Barrier | Moisture barrier |

Corona Treatment (Uncoated Side) |

Antistatic | Thermal Processing |

Applications | Remarks |

|---|---|---|---|---|---|---|---|---|---|

| 5000S | 20 | 10≧ | 4.0 | – | – | – | for Food packaging with water activity below 0.7 |

||

| 25 | 10≧ | 3.8 | – | – | – | for Food packaging with water activity below 0.7 |

Inquire please, regarding supply system. |

||

| 5050S | 25 | 10≧ | 3.8 | ○ | – | – | for Food packaging with water activity below 0.7 |

Inquire please, regarding supply system. |

|

| 500SFB | 20 | 10≧ | 4.0 | – | ○ | – | for Food packaging with water activity below 0.7 |

Inquire please, regarding supply system. |

|

| 5000X | 20 | 10≧ | 2.5 | – | – | – | for Food packaging with water activity below 0.7 |

||

| 5050X | 20 | 10≧ | 2.5 | ○ | – | – | for Food packaging with water activity below 0.7 |

Inquire please, regarding supply system. |

|

| 500XFB | 20 | 10≧ | 2.5 | – | ○ | – | for Food packaging with water activity below 0.7 |

Inquire please, regarding supply system. |

|

| 5000Y | 20 | 10≧ | 2.0 | – | – | – | for Food packaging with water activity below 0.7 |

||

| 30 | 10≧ | 1.5 | – | – | – | for Food packaging with water activity below 0.7 |

|||

| 5050Y | 20 | 10≧ | 2.0 | ○ | – | – | for Food packaging with water activity below 0.7 |

Inquire please, regarding supply system. |

|

| 500YFB | 30 | 10≧ | 1.5 | – | ○ | – | for Food packaging with water activity below 0.7 |

Inquire please, regarding supply system. |

* Unit: Oxygen barrier = ml/mi/24Hrs/MPa at 20°C ×80%RH

* Unit: Moisture barrier = g/m/24Hrs at 40°C ×90%RH

* The properties are representative values and not guaranteed values.