Water-Soluble Polymers Products

CELISH, TIARA

Microfibrillated Fibers

CELISH

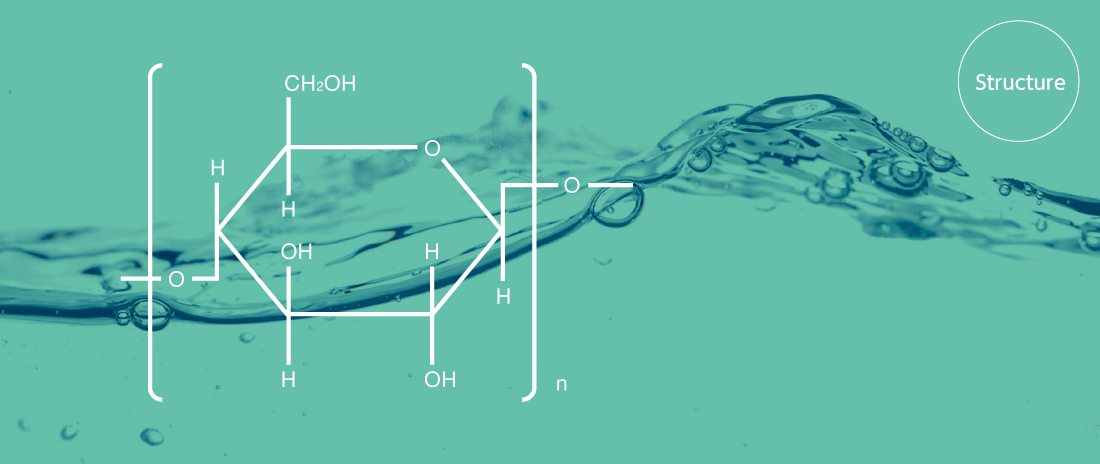

Microfibrillated Cellulose

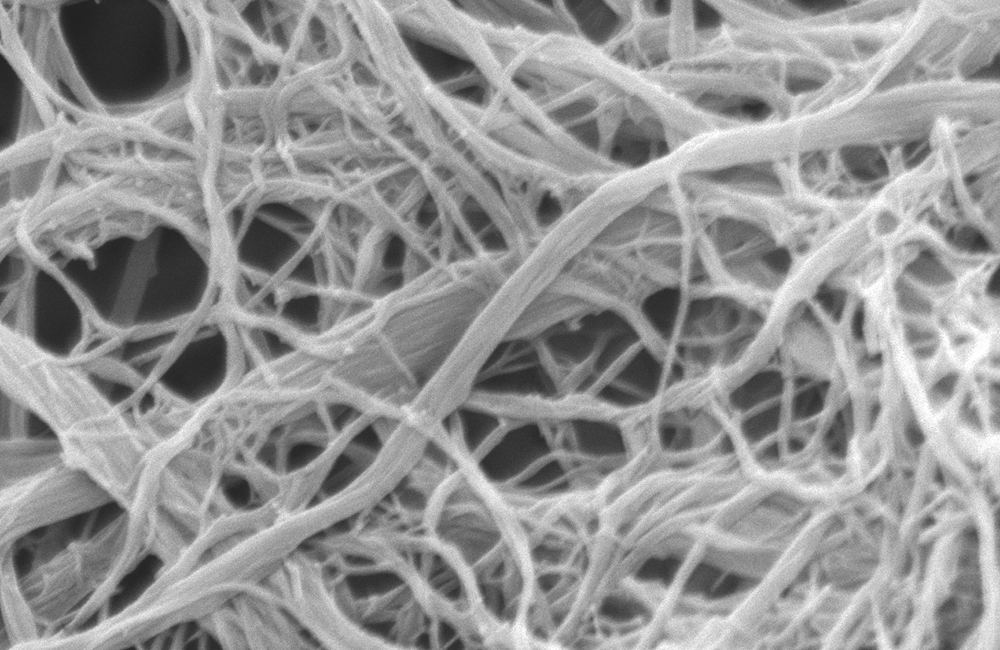

CELISH is cellulose fiber, microfibrillated by special manufacturing process, and is produced from highly refined, pure fiber raw materials. The raw material fiber is unraveled into tens of thousands of strands, and the fiber thickness is refined to between several μm and 0.01μm.

Because it is refined so that it does not impair the exact basic characteristics of the cellulose raw material (physical and chemical stability etc.), high-value-added product settings are possible.

Our microfibrillated fibers used for various applications; binder of fibers and powders, paper strength enhancer in paper making, texture improver in foods, filtration agent for liquors, etc.

[ Characteristics ]

· CELISH is a microfibrillated Cellulose produced by physically refining cellulose fiber without any chemical processing.

· It cannot dissolve, but it can disperse in water.

· It disperses uniformly in water and exhibits viscosity.

· The diameter of fibers has been reduced to as little as 0.1 to several micro meters.

· It’s great at picking up on tiny particles.

· It has excellent water retention.

[ Application ]

Food (Moisture Retention, Texture Improvement),

Japanese Sake, Shochu (Filtration Aid),

Paper Manufacturing(Strengthening Paper Quality),

Filter (improved aperture),

Cosmetics (face masks, peeling agents) etc.

CELISH Grade Lineup

| Category | Grade | Loss on Drying | Comment |

|---|---|---|---|

| Filtration Grades | PC110T | 63.0〜67.0% | |

| PC110A | 63.0〜67.0% | ||

| PC110B | 63.0〜67.0% | ||

| “Roka Meijin” | 63.0〜67.0% | ||

| PC110S | 63.0〜67.0% |

| Category | Grade | Loss on Drying | Comment |

|---|---|---|---|

| Food Grades | FD100F | 78.0〜82.0% | |

| FD100G | 89.0〜91.0% | ||

| FD200L | 78.0〜82.0% |

| Category | Grade | Solid Content | Comment |

|---|---|---|---|

| Industrial Grades | KY100S | 23.0〜27.0% | |

| KY100G | 9.0〜11.0% | Fine net structure |

TIARA

Microfibrillated Aramid

TIARA is a microfibrillated product made from aramid fiber, which is known for its excellent tensile strength and thermal resistance, and treated in a super-high-pressure homogenizer to give it high mechanical shearing strength. Shredding and refining the raw material fiber by microfibrillation, mainly in the direction of the fiber, allows us to obtain an aramid fiber with a microfibrillation that it did not possess originally.

[ Characteristics ]

Tiara is a microfiber material produced by physically refining synthetic aramid fiber without any chemical processing.Tiara is a microfiber material produced by physically refining aramid fiber—a synthetic fiber—without any chemical processing. While retaining the characteristic heat resistance, flame retardancy, high strength, and high elasticity of aramid fiber, Tiara significantly enhances water retention, filtration, breathability, adhesion, and paper strength (binder performance).

[ Applications ]

Electronics,

electrical materials, etc.

TIARA Grade Lineup

| Category | Grade | Solid Content | Comment |

|---|---|---|---|

| Industrial Grades | KY400S | 18.0〜22.0% | Microfibrillated Aramid Fiber |