Battery / Electronic materials

1. Lithium ion secondary batteries

Market of lithium ion secondary batteries had been increasing drastically, and our CMC had been used for anode of lithium ion battery.

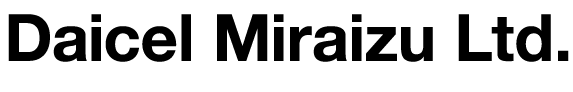

■Production process of anode

Making carbon paste by mixing anode material (carbon), water, binder (SBR, and CMC). Apply this carbon paste onto copper film and make anode.

※・・・Function of CMC in carbon paste are “thickener ”, “stabilizer”, “plasticizer”.

■CMC for lithium-ion battery

The most popular grade for lithium-ion battery is “CMC DAICEL 2200”.

<Specification of CMC DAICEL 2200>

| Moisture (%) |

Viscosity of (mPa・s) 60rpm |

pH | Degree of Substitution |

NaCl(%) |

|---|---|---|---|---|

| 10%max | 1,500~3,000 | 5.5~8.5 | 0.8~ | 1.0%max |

2. Surface treatment of electrolytic copper foil

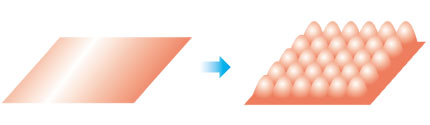

In production process of electrolytic copper foil, by adding HEC to electrolytic solution, surface of copper foil can be controlled properly.

■Image illustration of surface of copper foil

■HEC grade suitable for electrolytic copper foil

The most popular grade for production of electrolytic copper foil is “HEC DAICEL SP400”.

<Specification of HEC DAICEL SP400>

| Moisture(%) | Viscosity (mPa・s) 2%, 30rpm |

pH | Ash(%) |

|---|---|---|---|

| 5.0%max | 80~130 | 5.5~7.5 | 5.0%max |